Distillation is a process of separating component substances from liquid mixtures through vaporisation and condensation, based on different volatility (vaporization point) of components in the mixture. Distillation is a unit operation, or a physical separation process, and not a chemical reaction.

Commercially, distillation has a number of applications. It is used to separate crude oil into more fractions for specific uses such as transport, power generation and heating. Air is distilled to separate its components—notably oxygen, nitrogen, and argon—for industrial use. Liquid chemicals for diverse uses are distilled after synthesis to remove impurities and unreacted starting materials. Distillation of fermented solutions can produce distilled beverages

with a higher alcohol content. The premises where distillation is

carried out, especially distillation of alcohol, are known as a

distillery. A

still is the equipment used for distillation.

History

See also: Distilled beverage

Distillation apparatus of Zosimos of Panopolis, from Marcelin Berthelot,

Collection des anciens alchimistes grecs (3 vol., Paris, 1887–1888).

The first evidence of distillation comes from Greek alchemists working in Alexandria in the 1st century AD.

[2] Distilled water has been known since at least c. 200, when Alexander of Aphrodisias described the process.

[3] Distillation in China could have begun during the Eastern Han Dynasty (1st–2nd centuries), but archaeological evidence indicates that actual distillation of beverages began in the Jin and Southern Song dynasties.

[4] A still was found in an archaeological site in Qinglong, Hebei province dating to the 12th century. Distilled beverages were more common during the Yuan dynasty.

[4] Arabs learned the process from the Alexandrians and used it extensively in their chemical experiments.

[citation needed]

Clear evidence of the distillation of alcohol comes from the School of Salerno in the 12th century.

[2][5] Fractional distillation was developed by Tadeo Alderotti in the 13th century.

[6]

In 1500, German alchemist Hieronymus Braunschweig published

Liber de arte destillandi (The Book of the Art of Distillation)

[7] the first book solely dedicated to the subject of distillation, followed in 1512 by a much expanded version. In 1651, John French published The Art of Distillation the first major English compendium of practice, though it has been claimed

[8]

that much of it derives from Braunschweig's work. This includes

diagrams with people in them showing the industrial rather than bench

scale of the operation.

Hieronymus Brunschwig's

Liber de arte Distillandi de Compositis (Strassburg, 1512) Chemical Heritage Foundation

Old Ukrainian vodka still

Simple liqueur distillation in East Timor

As alchemy evolved into the science of chemistry, vessels called retorts became used for distillations. Both alembics and retorts are forms of glassware with long necks pointing to the side at a downward angle which acted as air-cooled condensers to condense

the distillate and let it drip downward for collection. Later, copper

alembics were invented. Riveted joints were often kept tight by using

various mixtures, for instance a dough made of rye flour.

[9]

These alembics often featured a cooling system around the beak, using

cold water for instance, which made the condensation of alcohol more

efficient. These were called pot stills.

Today, the retorts and pot stills have been largely supplanted by more

efficient distillation methods in most industrial processes. However,

the pot still is still widely used for the elaboration of some fine

alcohols such as cognac, Scotch whisky, tequila and some vodkas. Pot stills made of various materials (wood, clay, stainless steel) are also used by bootleggers in various countries. Small pot stills are also sold for the domestic production

[10] of flower water or essential oils.

Early forms of distillation were batch processes using one

vaporization and one condensation. Purity was improved by further

distillation of the condensate. Greater volumes were processed by simply

repeating the distillation. Chemists were reported to carry out as many

as 500 to 600 distillations in order to obtain a pure compound.

[11]

In the early 19th century the basics of modern techniques including pre-heating and reflux were developed, particularly by the French,

[11] then in 1830 a British Patent was issued to Aeneas Coffey for a whiskey distillation column,

[12] which worked continuously and may be regarded as the archetype of modern petrochemical units. In 1877, Ernest Solvay was granted a U.S. Patent for a tray column for ammonia distillation

[13] and the same and subsequent years saw developments of this theme for oil and spirits.

With the emergence of chemical engineering as a discipline at the end of the 19th century, scientific rather than empirical methods could be applied. The developing petroleum industry in the early 20th century provided the impetus for the development of accurate design methods such as the McCabe–Thiele method and the Fenske equation. The availability of powerful computers has also allowed direct computer simulation of distillation columns.

Applications of distillation

The application of distillation can roughly be divided in four groups: laboratory scale, industrial distillation, distillation of herbs for perfumery and medicinals (herbal distillate), and food processing.

The latter two are distinctively different from the former two in that

in the processing of beverages, the distillation is not used as a true

purification method but more to transfer all volatiles from the source materials to the distillate.

The main difference between laboratory scale distillation and

industrial distillation is that laboratory scale distillation is often

performed batch-wise, whereas industrial distillation often occurs

continuously. In batch distillation,

the composition of the source material, the vapors of the distilling

compounds and the distillate change during the distillation. In batch

distillation, a still is charged (supplied) with a batch of feed

mixture, which is then separated into its component fractions which are

collected sequentially from most volatile to less volatile, with the

bottoms (remaining least or non-volatile fraction) removed at the end.

The still can then be recharged and the process repeated.

In continuous distillation,

the source materials, vapors, and distillate are kept at a constant

composition by carefully replenishing the source material and removing

fractions from both vapor and liquid in the system. This results in a

better control of the separation process.

Idealized distillation model

The boiling point of a liquid is the temperature at which the vapor pressure of the liquid equals the pressure around the liquid, enabling bubbles to form without being crushed. A special case is the normal boiling point, where the vapor pressure of the liquid equals the ambient atmospheric pressure.

It is a common misconception that in a liquid mixture at a given

pressure, each component boils at the boiling point corresponding to the

given pressure and the vapors of each component will collect separately

and purely. This, however, does not occur even in an idealized system.

Idealized models of distillation are essentially governed by Raoult's law and Dalton's law, and assume that vapor–liquid equilibria are attained.

Raoult's law states that the vapor pressure of a solution is

dependent on 1) the vapor pressure of each chemical component in the

solution and 2) the fraction of solution each component makes up aka the

mole fraction. This law applies to ideal solutions,

or solutions that have different components but whose molecular

interactions are the same as or very similar to pure solutions.

Dalton's law states that the total vapor pressure is the sum of the

vapor pressures of each individual component in the mixture. When a

multi-component liquid is heated, the vapor pressure of each component

will rise, thus causing the total vapor pressure to rise. When the total

vapor pressure reaches the pressure surrounding the liquid, boiling

occurs and liquid turns to gas throughout the bulk of the liquid. Note

that a mixture with a given composition has one boiling point at a given

pressure, when the components are mutually soluble.

An implication of one boiling point is that lighter components never

cleanly "boil first". At boiling point, all volatile components boil,

but for a component, its percentage in the vapor is the same as its

percentage of the total vapor pressure. Lighter components have a higher

partial pressure and thus are concentrated in the vapor, but heavier

volatile components also have a (smaller) partial pressure and

necessarily evaporate also, albeit being less concentrated in the vapor.

Indeed, batch distillation and fractionation succeed by varying the

composition of the mixture. In batch distillation, the batch evaporates,

which changes its composition; in fractionation, liquid higher in the

fractionation column contains more lights and boils at lower

temperatures.

The idealized model is accurate in the case of chemically similar liquids, such as benzene and toluene.

In other cases, severe deviations from Raoult's law and Dalton's law

are observed, most famously in the mixture of ethanol and water. These

compounds, when heated together, form an azeotrope,

which is a composition with a boiling point higher or lower than the

boiling point of each separate liquid. Virtually all liquids, when mixed

and heated, will display azeotropic behaviour. Although there are computational methods that can be used to estimate the behavior of a mixture of arbitrary components, the only way to obtain accurate vapor–liquid equilibrium data is by measurement.

It is not possible to

completely purify a mixture of components by distillation, as this would require each component in the mixture to have a zero partial pressure. If ultra-pure products are the goal, then further chemical separation

must be applied. When a binary mixture is evaporated and the other

component, e.g. a salt, has zero partial pressure for practical

purposes, the process is simpler and is called evaporation in engineering.

Batch distillation

Main article: Batch distillation

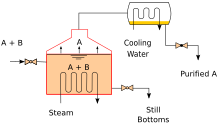

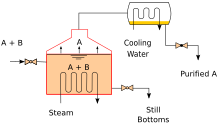

A batch still showing the separation of A and B.

Heating an ideal mixture of two volatile substances A and B (with A

having the higher volatility, or lower boiling point) in a batch

distillation setup (such as in an apparatus depicted in the opening

figure) until the mixture is boiling results in a vapor above the liquid

which contains a mixture of A and B. The ratio between A and B in the

vapor will be different from the ratio in the liquid: the ratio in the

liquid will be determined by how the original mixture was prepared,

while the ratio in the vapor will be enriched in the more volatile

compound, A (due to Raoult's Law, see above). The vapor goes through the

condenser and is removed from the system. This in turn means that the

ratio of compounds in the remaining liquid is now different from the

initial ratio (i.e., more enriched in B than the starting liquid).

The result is that the ratio in the liquid mixture is changing,

becoming richer in component B. This causes the boiling point of the

mixture to rise, which in turn results in a rise in the temperature in

the vapor, which results in a changing ratio of A : B in the gas phase

(as distillation continues, there is an increasing proportion of B in

the gas phase). This results in a slowly changing ratio A : B in the

distillate.

If the difference in vapor pressure between the two components A and B

is large (generally expressed as the difference in boiling points), the

mixture in the beginning of the distillation is highly enriched in

component A, and when component A has distilled off, the boiling liquid

is enriched in component B.

Continuous distillation

Main article: Continuous distillation

Continuous distillation is an ongoing distillation in which a liquid

mixture is continuously (without interruption) fed into the process and

separated fractions are removed continuously as output streams as time

passes during the operation. Continuous distillation produces at least

two output fractions, including at least one volatile

distillate fraction, which has boiled and been separately captured as a

vapor condensed to a liquid. There is always a bottoms (or residue)

fraction, which is the least volatile residue that has not been

separately captured as a condensed vapor.

Continuous distillation differs from batch distillation in the

respect that concentrations should not change over time. Continuous

distillation can be run at a steady state

for an arbitrary amount of time. For any source material of specific

composition, the main variables that affect the purity of products in

continuous distillation are the reflux ratio and the number of

theoretical equilibrium stages (practically, the number of trays or the

height of packing). Reflux is a flow from the condenser back to the

column, which generates a recycle that allows a better separation with a

given number of trays. Equilibrium stages are ideal steps where

compositions achieve vapor–liquid equilibrium, repeating the separation

process and allowing better separation given a reflux ratio. A column

with a high reflux ratio may have fewer stages, but it refluxes a large

amount of liquid, giving a wide column with a large holdup. Conversely, a

column with a low reflux ratio must have a large number of stages, thus

requiring a taller column.

General improvements

Both batch and continuous distillations can be improved by making use of a fractionating column

on top of the distillation flask. The column improves separation by

providing a larger surface area for the vapor and condensate to come

into contact. This helps it remain at equilibrium for as long as

possible. The column can even consist of small subsystems ('trays' or

'dishes') which all contain an enriched, boiling liquid mixture, all

with their own vapor–liquid equilibrium.

There are differences between laboratory-scale and industrial-scale

fractionating columns, but the principles are the same. Examples of

laboratory-scale fractionating columns (in increasing efficiency)

include

- Air condenser

- Vigreux column (usually laboratory scale only)

- Packed column (packed with glass beads, metal pieces, or other chemically inert material)

- Spinning band distillation system.

Laboratory scale distillation

Typical laboratory distillation unit

Laboratory scale distillations are almost exclusively run as batch

distillations. The device used in distillation, sometimes referred to as

a

still, consists at a minimum of a

reboiler or

pot in which the source material is heated, a

condenser in which the heated vapour is cooled back to the liquid state, and a

receiver in which the concentrated or purified liquid, called the

distillate, is collected. Several laboratory scale techniques for distillation exist (see also distillation types).

Simple distillation

In

simple distillation, the vapor is immediately channeled

into a condenser. Consequently, the distillate is not pure but rather

its composition is identical to the composition of the vapors at the

given temperature and pressure. That concentration follows Raoult's law.

As a result, simple distillation is effective only when the liquid boiling points differ greatly (rule of thumb is 25 °C)

[14]

or when separating liquids from non-volatile solids or oils. For these

cases, the vapor pressures of the components are usually sufficiently

different that the distillate may be sufficiently pure for its intended

purpose.

Fractional distillation

Main article: Fractional distillation

For many cases, the boiling points of the components in the mixture

will be sufficiently close that Raoult's law must be taken into

consideration. Therefore,

fractional distillation must be used in

order to separate the components by repeated vaporization-condensation

cycles within a packed fractionating column. This separation, by

successive distillations, is also referred to as

rectification.

[15]

As the solution to be purified is heated, its vapors rise to the fractionating column.

As it rises, it cools, condensing on the condenser walls and the

surfaces of the packing material. Here, the condensate continues to be

heated by the rising hot vapors; it vaporizes once more. However, the

composition of the fresh vapors are determined once again by Raoult's

law. Each vaporization-condensation cycle (called a

theoretical plate) will yield a purer solution of the more volatile component.

[16] In reality, each cycle at a given temperature does not occur at exactly the same position in the fractionating column;

theoretical plate is thus a concept rather than an accurate description.

More theoretical plates lead to better separations. A spinning band distillation system uses a spinning band of Teflon

or metal to force the rising vapors into close contact with the

descending condensate, increasing the number of theoretical plates.

[17]

Steam distillation

Main article: Steam distillation

Like vacuum distillation,

steam distillation is a method for distilling compounds which are heat-sensitive.

[18]

The temperature of the steam is easier to control than the surface of a

heating element, and allows a high rate of heat transfer without

heating at a very high temperature. This process involves bubbling steam

through a heated mixture of the raw material. By Raoult's law, some of

the target compound will vaporize (in accordance with its partial

pressure). The vapor mixture is cooled and condensed, usually yielding a

layer of oil and a layer of water.

Steam distillation of various aromatic herbs and flowers can result in two products; an essential oil as well as a watery herbal distillate. The essential oils are often used in perfumery and aromatherapy while the watery distillates have many applications in aromatherapy, food processing and skin care.

Dimethyl sulfoxide usually boils at 189 °C. Under a vacuum, it distills off into the receiver at only 70 °C.

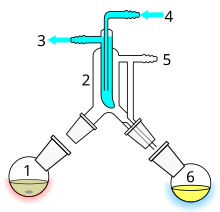

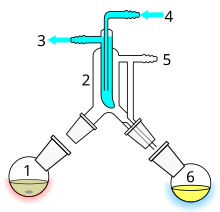

Perkin triangle distillation setup1:

Stirrer bar/anti-bumping granules

2: Still pot

3: Fractionating column

4: Thermometer/Boiling point temperature

5: Teflon tap 1

6: Cold finger

7: Cooling water out

8: Cooling water in

9: Teflon tap 2

10: Vacuum/gas inlet

11: Teflon tap 3

12: Still receiver

Vacuum distillation

Main article: Vacuum distillation

Some compounds have very high boiling points. To boil such compounds,

it is often better to lower the pressure at which such compounds are

boiled instead of increasing the temperature. Once the pressure is

lowered to the vapor pressure of the compound (at the given

temperature), boiling and the rest of the distillation process can

commence. This technique is referred to as

vacuum distillation and it is commonly found in the laboratory in the form of the rotary evaporator.

This technique is also very useful for compounds which boil beyond their decomposition temperature at atmospheric pressure and which would therefore be decomposed by any attempt to boil them under atmospheric pressure.

Molecular distillation is vacuum distillation below the pressure of 0.01 torr.

[19] 0.01 torr is one order of magnitude above high vacuum, where fluids are in the free molecular flow regime, i.e. the mean free path

of molecules is comparable to the size of the equipment. The gaseous

phase no longer exerts significant pressure on the substance to be

evaporated, and consequently, rate of evaporation no longer depends on

pressure. That is, because the continuum assumptions of fluid dynamics

no longer apply, mass transport is governed by molecular dynamics rather

than fluid dynamics. Thus, a short path between the hot surface and the

cold surface is necessary, typically by suspending a hot plate covered

with a film of feed next to a cold plate with a line of sight in

between. Molecular distillation is used industrially for purification of

oils.

Air-sensitive vacuum distillation

Some compounds have high boiling points as well as being air sensitive.

A simple vacuum distillation system as exemplified above can be used,

whereby the vacuum is replaced with an inert gas after the distillation

is complete. However, this is a less satisfactory system if one desires

to collect fractions under a reduced pressure. To do this a "cow" or

"pig" adaptor can be added to the end of the condenser, or for better

results or for very air sensitive compounds a Perkin triangle apparatus can be used.

The Perkin triangle, has means via a series of glass or Teflon taps to allows fractions to be isolated from the rest of the still,

without the main body of the distillation being removed from either the

vacuum or heat source, and thus can remain in a state of reflux.

To do this, the sample is first isolated from the vacuum by means of

the taps, the vacuum over the sample is then replaced with an inert gas

(such as nitrogen or argon)

and can then be stoppered and removed. A fresh collection vessel can

then be added to the system, evacuated and linked back into the

distillation system via the taps to collect a second fraction, and so

on, until all fractions have been collected.

Short path distillation

Short path vacuum distillation apparatus with vertical condenser (cold finger), to minimize the distillation path;

1: Still pot with stirrer bar/anti-bumping granules

2: Cold finger – bent to direct condensate

3: Cooling water out

4: cooling water in

5: Vacuum/gas inlet

6: Distillate flask/distillate.

Short path distillation is a distillation technique that

involves the distillate travelling a short distance, often only a few

centimeters, and is normally done at reduced pressure.

[20]

A classic example would be a distillation involving the distillate

travelling from one glass bulb to another, without the need for a

condenser separating the two chambers. This technique is often used for

compounds which are unstable at high temperatures or to purify small

amounts of compound. The advantage is that the heating temperature can

be considerably lower (at reduced pressure) than the boiling point of

the liquid at standard pressure, and the distillate only has to travel a

short distance before condensing. A short path ensures that little

compound is lost on the sides of the apparatus. The Kugelrohr is a kind of a short path distillation apparatus which often contain multiple chambers to collect distillate fractions.

Zone distillation

Zone distillation is a distillation process in long container with

partial melting of refined matter in moving liquid zone and condensation

of vapor in the solid phase at condensate pulling in cold area. The

process is worked in theory. When zone heater is moving from the top to

the bottom of the container then solid condensate with irregular

impurity distribution is forming. Then most pure part of the condensate

may be extracted as product. The process may be iterated many times by

moving (without turnover) the received condensate to the bottom part of

the container on the place of refined matter. The irregular impurity

distribution in the condensate (that is efficiency of purification)

increases with number of repetitions of the process. Zone distillation

is a distillation analog of zone recrystallization. Impurity

distribution in the condensate is described by known equations of zone

recrystallization with various numbers of iteration of process – with

replacement distribution efficient k of crystallization on separation

factor α of distillation.

[21][22]

Other types

- The process of reactive distillation

involves using the reaction vessel as the still. In this process, the

product is usually significantly lower-boiling than its reactants. As

the product is formed from the reactants, it is vaporized and removed

from the reaction mixture. This technique is an example of a continuous

vs. a batch process; advantages include less downtime to charge the

reaction vessel with starting material, and less workup. Distillation

"over a reactant" could be classified as a reactive distillation. It is

typically used to remove volatile impurity from the distallation feed.

For example a little lime may be added to remove carbon dioxide from water followed by a second distillation with a little sulphuric acid added to remove traces of ammonia.

- Catalytic distillation

is the process by which the reactants are catalyzed while being

distilled to continuously separate the products from the reactants. This

method is used to assist equilibrium reactions reach completion.

- Pervaporation is a method for the separation of mixtures of liquids by partial vaporization through a non-porous membrane.

- Extractive distillation

is defined as distillation in the presence of a miscible, high boiling,

relatively non-volatile component, the solvent, that forms no azeotrope with the other components in the mixture.

- Flash evaporation (or partial evaporation) is the partial vaporization that occurs when a saturated liquid stream undergoes a reduction in pressure by passing through a throttling valve

or other throttling device. This process is one of the simplest unit

operations, being equivalent to a distillation with only one equilibrium

stage.

- Codistillation is distillation which is performed on mixtures in which the two compounds are not miscible.

The unit process of evaporation may also be called "distillation":

- In rotary evaporation a vacuum distillation apparatus is used to remove bulk solvents from a sample. Typically the vacuum is generated by a water aspirator or a membrane pump.

- In a kugelrohr

a short path distillation apparatus is typically used (generally in

combination with a (high) vacuum) to distill high boiling (> 300 °C)

compounds. The apparatus consists of an oven in which the compound to be

distilled is placed, a receiving portion which is outside of the oven,

and a means of rotating the sample. The vacuum is normally generated by

using a high vacuum pump.

Other uses:

- Dry distillation or destructive distillation, despite the name, is not truly distillation, but rather a chemical reaction known as pyrolysis in which solid substances are heated in an inert or reducing

atmosphere and any volatile fractions, containing high-boiling liquids

and products of pyrolysis, are collected. The destructive distillation

of wood to give methanol is the root of its common name – wood alcohol.

- Freeze distillation is an analogous method of purification using freezing instead of evaporation. It is not truly distillation, but a recrystallization where the product is the mother liquor, and does not produce products equivalent to distillation. This process is used in the production of ice beer and ice wine to increase ethanol and sugar content, respectively. It is also used to produce applejack.

Unlike distillation, freeze distillation concentrates poisonous

congeners rather than removing them; As a result, many countries

prohibit such applejack as a health measure. However, reducing methanol

with the absorption of 4A molecular sieve is a practical method for production.[23] Also, distillation by evaporation can separate these since they have different boiling points.

Azeotropic distillation

Main article: Azeotropic distillation

Interactions between the components of the solution create properties

unique to the solution, as most processes entail nonideal mixtures,

where Raoult's law does not hold. Such interactions can result in a constant-boiling

azeotrope

which behaves as if it were a pure compound (i.e., boils at a single

temperature instead of a range). At an azeotrope, the solution contains

the given component in the same proportion as the vapor, so that

evaporation does not change the purity, and distillation does not effect

separation. For example, ethyl alcohol and water form an azeotrope of 95.6% at 78.1 °C.

If the azeotrope is not considered sufficiently pure for use, there

exist some techniques to break the azeotrope to give a pure distillate.

This set of techniques are known as

azeotropic distillation. Some

techniques achieve this by "jumping" over the azeotropic composition

(by adding an additional component to create a new azeotrope, or by

varying the pressure). Others work by chemically or physically removing

or sequestering the impurity. For example, to purify ethanol beyond 95%,

a drying agent or a (desiccant such as potassium carbonate) can be added to convert the soluble water into insoluble water of crystallization. Molecular sieves are often used for this purpose as well.

Immiscible liquids, such as water and toluene,

easily form azeotropes. Commonly, these azeotropes are referred to as a

low boiling azeotrope because the boiling point of the azeotrope is

lower than the boiling point of either pure component. The temperature

and composition of the azeotrope is easily predicted from the vapor

pressure of the pure components, without use of Raoult's law. The

azeotrope is easily broken in a distillation set-up by using a

liquid–liquid separator (a decanter) to separate the two liquid layers

that are condensed overhead. Only one of the two liquid layers is

refluxed to the distillation set-up.

High boiling azeotropes, such as a 20 weight percent mixture of

hydrochloric acid in water, also exist. As implied by the name, the

boiling point of the azeotrope is greater than the boiling point of

either pure component.

To break azeotropic distillations and cross distillation boundaries,

such as in the DeRosier Problem, it is necessary to increase the

composition of the light key in the distillate.

Breaking an azeotrope with unidirectional pressure manipulation

The boiling points of components in an azeotrope overlap to form a

band. By exposing an azeotrope to a vacuum or positive pressure, it's

possible to bias the boiling point of one component away from the other

by exploiting the differing vapour pressure curves of each; the curves

may overlap at the azeotropic point, but are unlikely to be remain

identical further along the pressure axis either side of the azeotropic

point. When the bias is great enough, the two boiling points no longer

overlap and so the azeotropic band disappears.

This method can remove the need to add other chemicals to a distillation, but it has two potential drawbacks.

Under negative pressure, power for a vacuum source is needed and the

reduced boiling points of the distillates requires that the condenser be

run cooler to prevent distillate vapours being lost to the vacuum

source. Increased cooling demands will often require additional energy

and possibly new equipment or a change of coolant.

Alternatively, if positive pressures are required, standard glassware

can not be used, energy must be used for pressurization and there is a

higher chance of side reactions occurring in the distillation, such as

decomposition, due to the higher temperatures required to effect

boiling.

A unidirectional distillation will rely on a pressure change in one direction, either positive or negative.

Pressure-swing distillation

Further information: Pressure-Swing Distillation (section on the main Azeotrope page)

Pressure-swing distillation is essentially the same as the

unidirectional distillation used to break azeotropic mixtures, but here

both positive and negative pressures may be employed.

This improves the selectivity of the distillation and allows a

chemist to optimize distillation by avoiding extremes of pressure and

temperature that waste energy. This is particularly important in

commercial applications.

One example of the application of pressure-swing distillation is during the industrial purification of ethyl acetate after its catalytic synthesis from ethanol.

Industrial distillation

Typical industrial distillation towers

Main article: Continuous distillation

Large scale

industrial distillation applications include both

batch and continuous fractional, vacuum, azeotropic, extractive, and

steam distillation. The most widely used industrial applications of

continuous, steady-state fractional distillation are in petroleum refineries, petrochemical and chemical plants and natural gas processing plants.

To control and optimize such industrial distillation, a standardized

laboratory method, ASTM D86, is established. This test method extends to

the atmospheric distillation of petroleum products using a laboratory

batch distillation unit to quantitatively determine the boiling range

characteristics of petroleum products.

Automatic Distillation Unit for the determination of the boiling range of petroleum products at atmospheric pressure

Industrial distillation

[15][24] is typically performed in large, vertical cylindrical columns known as

distillation towers or

distillation columns

with diameters ranging from about 65 centimeters to 16 meters and

heights ranging from about 6 meters to 90 meters or more. When the

process feed has a diverse composition, as in distilling crude oil, liquid outlets at intervals up the column allow for the withdrawal of different

fractions or products having different boiling points

or boiling ranges. The "lightest" products (those with the lowest

boiling point) exit from the top of the columns and the "heaviest"

products (those with the highest boiling point) exit from the bottom of

the column and are often called the

bottoms.

Diagram of a typical industrial distillation tower

Industrial towers use reflux

to achieve a more complete separation of products. Reflux refers to the

portion of the condensed overhead liquid product from a distillation or

fractionation tower that is returned to the upper part of the tower as

shown in the schematic diagram of a typical, large-scale industrial

distillation tower. Inside the tower, the downflowing reflux liquid

provides cooling and condensation of the upflowing vapors thereby

increasing the efficiency of the distillation tower. The more reflux

that is provided for a given number of theoretical plates,

the better the tower's separation of lower boiling materials from

higher boiling materials. Alternatively, the more reflux that is

provided for a given desired separation, the fewer the number of

theoretical plates required. Chemical engineers

must choose what combination of reflux rate and number of plates is

both economically and physically feasible for the products purified in

the distillation column.

Such industrial fractionating towers are also used in cryogenic air separation, producing liquid oxygen, liquid nitrogen, and high purity argon. Distillation of chlorosilanes also enables the production of high-purity silicon for use as a semiconductor.

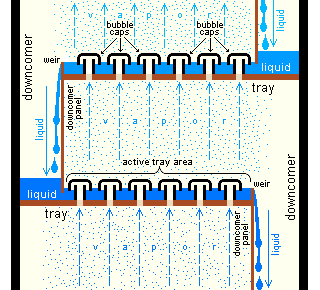

Section of an industrial distillation tower showing detail of trays with bubble caps

Design and operation of a distillation tower depends on the feed and

desired products. Given a simple, binary component feed, analytical

methods such as the McCabe–Thiele method

[15][25] or the Fenske equation

[15] can be used. For a multi-component feed, simulation

models are used both for design and operation. Moreover, the

efficiencies of the vapor–liquid contact devices (referred to as

"plates" or "trays") used in distillation towers are typically lower

than that of a theoretical 100% efficient equilibrium stage.

Hence, a distillation tower needs more trays than the number of

theoretical vapor–liquid equilibrium stages. A variety of models have

been postulated to estimate tray efficiencies.

In modern industrial uses, a packing material is used in the column

instead of trays when low pressure drops across the column are required.

Other factors that favor packing are: vacuum systems, smaller diameter

columns, corrosive systems, systems prone to foaming, systems requiring

low liquid holdup, and batch distillation. Conversely, factors that

favor plate columns

are: presence of solids in feed, high liquid rates, large column

diameters, complex columns, columns with wide feed composition

variation, columns with a chemical reaction, absorption columns, columns

limited by foundation weight tolerance, low liquid rate, large

turn-down ratio and those processes subject to process surges.

Large-scale, industrial vacuum distillation column

[26]

This packing material can either be random dumped packing (1–3" wide) such as Raschig rings or structured sheet metal. Liquids tend to wet the surface of the packing and the vapors pass across this wetted surface, where mass transfer

takes place. Unlike conventional tray distillation in which every tray

represents a separate point of vapor–liquid equilibrium, the

vapor–liquid equilibrium curve in a packed column is continuous.

However, when modeling packed columns, it is useful to compute a number

of "theoretical stages" to denote the separation efficiency of the

packed column with respect to more traditional trays. Differently shaped

packings have different surface areas and void space between packings.

Both of these factors affect packing performance.

Another factor in addition to the packing shape and surface area that

affects the performance of random or structured packing is the liquid

and vapor distribution entering the packed bed. The number of theoretical stages

required to make a given separation is calculated using a specific

vapor to liquid ratio. If the liquid and vapor are not evenly

distributed across the superficial tower area as it enters the packed

bed, the liquid to vapor ratio will not be correct in the packed bed and

the required separation will not be achieved. The packing will appear

to not be working properly. The height equivalent to a theoretical plate

(HETP) will be greater than expected. The problem is not the packing

itself but the mal-distribution of the fluids entering the packed bed.

Liquid mal-distribution is more frequently the problem than vapor. The

design of the liquid distributors used to introduce the feed and reflux

to a packed bed is critical to making the packing perform to it maximum

efficiency. Methods of evaluating the effectiveness of a liquid

distributor to evenly distribute the liquid entering a packed bed can be

found in references.

[27][28] Considerable work as been done on this topic by Fractionation Research, Inc. (commonly known as FRI).

[29]

Multi-effect distillation

The goal of multi-effect distillation is to increase the energy

efficiency of the process, for use in desalination, or in some cases one

stage in the production of ultrapure water. The number of effects is

inversely proportional to the kW·h/m

3 of water recovered

figure, and refers to the volume of water recovered per unit of energy

compared with single-effect distillation. One effect is roughly

636 kW·h/m

3.

- Multi-stage flash distillation Can achieve more than 20 effects with thermal energy input, as mentioned in the article.

- Vapor compression evaporation Commercial large-scale units can achieve around 72 effects with electrical energy input, according to manufacturers.

There are many other types of multi-effect distillation processes,

including one referred to as simply multi-effect distillation (MED), in

which multiple chambers, with intervening heat exchangers, are employed.

Distillation in food processing

Distilled beverages

Main article: Distilled beverage

Carbohydrate-containing plant materials are allowed to ferment, producing a dilute solution of ethanol in the process. Spirits such as whiskey and rum

are prepared by distilling these dilute solutions of ethanol.

Components other than ethanol, including water, esters, and other

alcohols, are collected in the condensate, which account for the flavor

of the beverage. Some of these beverages are then stored in barrels or

other containers to acquire more flavor compounds and characteristic

flavors.

Gallery

|

Chemistry in its beginnings used retorts as laboratory equipment exclusively for distillation processes. |

|

A simple set-up to distill dry and oxygen-free toluene. |

|

Diagram of an industrial-scale vacuum distillation column as commonly used in oil refineries |

|

A rotary evaporator is able to distill solvents more quickly at lower temperatures through the use of a vacuum. |

|

Distillation using semi-microscale apparatus. The jointless design

eliminates the need to fit pieces together. The pear-shaped flask allows

the last drop of residue to be removed, compared with a similarly-sized

round-bottom flask

The small holdup volume prevents losses. A pig is used to channel the

various distillates into three receiving flasks. If necessary the

distillation can be carried out under vacuum using the vacuum adapter at

the pig. |